品牌

其他厂商性质

所在地

ABB大功率机器人系列开辟了全新的应用领域,该机器人有多种版本,大承重能力高达650kg。IRB 7600适合用于各行业重载场合,大转矩、大惯性、刚性结构以及的加速性能等优良特性使这款市场主导产品声誉日隆。

§ 可靠性强——正常运行时间长

§ 安全性高——安全的投资

§ 速度快——操作周期时间短

§ 精度高——零件生产质量稳定

§ 功率大——适用范围广

§ 坚固耐用——适合恶劣生产环境

§ 通用性——柔性化集成和生产

| 机器人版本 | 到达距离 | 承重能力 | 重心 | 手腕大转矩 |

| IRB 7600-500 | 2.55 m | 500 kg | 360 mm | 3010 Nm |

| IRB 7600-400 | 2.55 m | 400 kg | 512 mm | 3010 Nm |

| IRB 7600-340 | 2.80 m | 340 kg | 360 mm | 2750 Nm |

| IRB 7600-325 | 3.10 m | 325 kg | 360 mm | 2680 Nm |

| IRB 7600-150 | 3.50 m | 150 kg | 360 mm | 1880 Nm |

| IRB 7600-150 (loaded with 100 kg) |

|

| 1660 mm |

|

The IRB 7600FX raises the bar in Press Automation to provide customers with more flexibility at greater speeds while saving precious press-shop floor space.

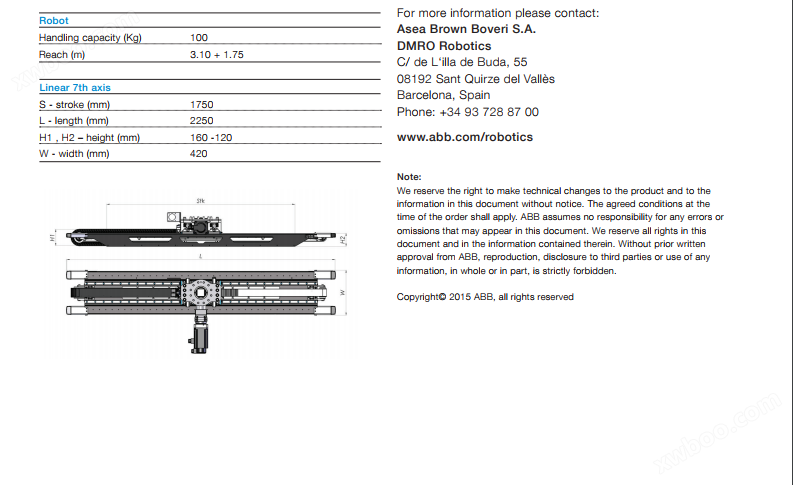

Linear part transfer By integrating a dual action unit into IRB 7600, ABB creates the IRB 7600FX, a 7-axis robot for the transfer of large parts rapidly along a linear path. As a result, vibrations created when parts are rotated 180º by the con- ventional 6-axis robot are eliminated In the case of new press lines, Inter-press distance can be reduced as parts are transferred withou having to be rotated Dynamic model control The IRB 7600FX is also equipped with integrated dynamic model control to ensure the that all seven axes are coordinated and operating at optimum speed and lifetime. User-friendly programming interface The IRB 7600FX is programmed the same way as its 6-axis counterpart is. Additionally, it can be programmed using ABB’s StampWare.

StampWare Currently running in more than 1,000 units worldwide, StampWare is a family of controller software designed to make you more productive by minimizing the rearning time and setup time of new production, The modularized program structure, the program wizard and the graphical production window decrease the time for training that the operator and robot programmer need. As a result , production is more efficient during installation, production ser-up and optimizing of the robot cycle. Optimized performance with carbon fiber tooling The IRB 7600FX’s carbon fiber tooling increases output thanks to its specially designed shape which has been optimized for tool height. As a result it can be placed into the die at lower press openings