功能特点

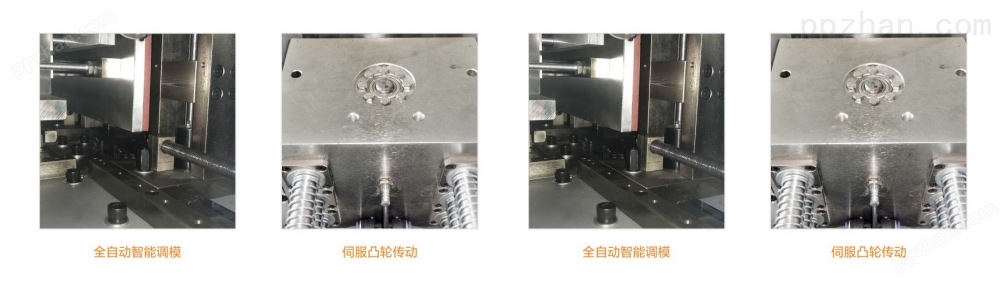

该机融纸盒的包边、折入,压泡为一体,运用伺服驱动斜齿轮和凸轮完成连贯动作,稳定流畅,精密耐用,是目前相对合理的一款成型机,也是广大礼品盒生产厂家的明智必选机型。

功能特点

1.主轴、分模、刷辊、折边、压泡全部由伺服驱动, 运转稳定安静。流畅快捷。

2.*的凸轮、气缸两次盒体除泡功能,可根据情况选择一次或两次压泡。储气可调式底模升降设计,对纸盒底部除泡力度可调可控。

3.斜齿机构传动主轴动作,稳定、精确、牢国、产量高使用寿命长,整机可实现播放式慢动作运行,而凸轮机构更可以获得平稳的运动.当速度改变时也可以保持同步,调试时更容易观察到生产过程。

4.折耳动作可做对搭80mm,导轨加气缸,精密度高,行程可定制,能适应不同产品的生产需求。

5.真空吸盒压力可调,大小可选不同压力,有助于人工套盒时的顺畅与速度,

6.快速换模调机设计,程序记忆功能,十五分钟完成转版。

7.进口光栅保护,故障报警,故障区显示,保障运行操作的安全。

8.加厚台板,加厚机架,CNC加工中心次完成.确保运行稳定性和装配标准化。

9.免换折边铲刀和压泡板,从小到大的纸盒都可使用,

10.调节方式可手动也可以升级为自动,锁固方式可选配。

Functional features

This machine integrates wrapping, folding and pressing of carton into one, and uses servo driven helical gear and cam to complete continuous action. It is stable, smooth, precise and durable. It is a relatively reasonable molding machine at present, and also a wise and necessary model for the majority of gift box manufacturers.

Features

1. The spindle, parting die, brush roller, flanging and bubble pressing are all driven by servo, so the operation is stable and quiet. Smooth and fast.

2. The unique function of twice bubble removing for cam and cylinder can be selected once or twice according to the situation. The air storage adjustable bottom mold lifting design can adjust and control the defoaming force at the bottom of the carton.

3. The helical gear mechanism drives the spindle action, which is stable, accurate, reliable, high output, long service life. The whole machine can realize the slow motion operation of play type, and the cam mechanism can obtain more stable movement. When the speed changes, it can also keep synchronous, and it is easier to observe the production process during debugging.

4. The action of ear folding can be set to 80mm. The guide rail and cylinder have high precision. The stroke can be customized to meet the production needs of different products.

5. The pressure of vacuum suction box can be adjusted, and different pressures can be selected, which is conducive to the smoothness and speed of manual box setting,

6. Quick mold changing and adjusting machine design, program memory function, 15 minutes to complete version transfer.

7. Imported grating protection, fault alarm, fault area display, ensure the safety of operation.

8. Thickened platen, thickened frame and CNC machining center are completed one time to ensure operation stability and assembly standardization.

9. No need to change the folding blade and pressure foam board, which can be used from small to large cartons,

10. The adjustment mode can be manual or upgraded to automatic, and the locking mode can be selected.