品牌

厂商性质

广州市所在地

SCGX-2-1B 全自动酱料灌装和真空旋盖一体机

SCGX-2-1B Automatic sauce filling and vacuum capping machine

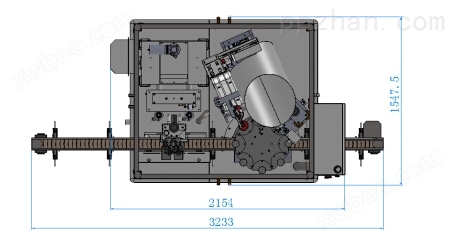

1.图片( Picture):

2.概述(Abstract) :

该机是我司的*产品,集灌装和真空旋盖于一体,占地面积小,智能高效,市场空白,广泛适用于各类膏体、酱料(玻璃瓶马口铁盖包装)自动定量灌装和真空旋盖。

This machine is our original new high-tech product. It integrates filling and vacuum capping in one machine. it is smart and efficient as it covers small footprint, filled up the market gap and widely used in all kinds of pastes and sauces (glass bottle tinplate lid packing ) Automatic quantitative filling and vacuum capping.

3.主要性能特点(Main performance features):

l该机集自动定量灌装和真空旋盖于一体,占地面积小,自动化程度高,操作简单,维护方便;

This machine integrates automatic quantitative filling and vacuum capping, and it covers a small footprint, has high degree of automation, simple to operate and easy to maintain;

l该机采用PLC配合人机界面(触摸屏)控制,主要电器和气动元件采用国内外品牌,确保性能稳定,可靠,耐用;

For this machine PLC with man-machine interface (touching screen) control was adopted, and for the main electrical and pneumatic components we choose domestic Well-known brands to ensure stable performance, reliability, and durability;

l该机外壳、机架、主体结构等主要采用304#不锈钢制作,外形美观;

The shell, frame, main structure, etc. of the machine are mainly made from 304# stainless steel so it is with beautiful appearance;

l该机灌装过物料机构、管道均采用卫生级SUS304和食品级塑料制作,快装活接,拆洗简单快捷,符合食品卫生要求;

In this machine the parts and pipes that contact the material are made of grade SUS304 stainless steel and food grade plastics. Connected, easy to take apart and wash, in line with food hygiene requirements

l灌装量调整仅需在触摸屏上更改参数即可,非常直观便捷;

It is very intuitive and convenient as when to adjust the filling volume only needs to change parameters on the touching screen;

l采用编码器控制活塞运动进行计量,灌装精度高,灌装头设有防滴漏装置,确保灌装不滴漏;

The encoder is used to control the movement of the piston for measurement, and the filling accuracy is high. The filling head is provided with a drip-proof device to ensure that the filling does not leak;

l本机采用吸盖上盖,倒旋认口预旋,密封真空旋盖等技术,确保上盖准确,旋盖合格率高;

The use of suction lid cover, reverse rotation pre-rotation, sealing vacuum capping technology, is to ensure that the cover is accurate and the capping pass rate is high;

l采用密闭腔真空泵抽真空然后旋盖的方式,可确保获得高真空度;

A closed-chamber vacuum pump is used to vacuum and then screw caps, Which ensures high vacuum levels;

l旋盖扭力及真空度可按需设定;

Capping torque and vacuum degree can be set according to requirements;

l更换少量部件,即可适合于不同尺寸瓶子的真空旋盖。

With a small number of parts replacing, vacuum caps can be suitable for different sizes of bottles.

4. 主要技术参数

灌装物料:各类膏体、酱料 灌装旋盖速度:1300-1500瓶/时

灌装范围:100-500g 灌装精度:≤±1%

电源电压:380V/50~60Hz 功 率:≤3.0KW (含真空泵)

气源气压:大于0.6Mpa 耗气量:约0.5M3/0.5Mpa

真空度:-0.07mpa 旋盖扭力:5-20N.M

适应瓶高:50-180㎜ 适应瓶径:ф35-ф110mm

适应瓶盖:ф35-ф95mm 重量:约750kg

4. Specification

Materials: all kinds of pastes, sauces Speed: 1300-1500 bottles/hour

Range:100-500g Tolerance:≤±1%

Voltage:380V/50~60Hz Power:≤3.0KW(Vacuum pump included)

Air pressure:>0.6Mpa Air consumption:around 0.5M3/0.5Mpa

Max Vacuum degree:-0.07mpa Capping torque:5-20N.M

bottle height range:50-180㎜ Bottle diameter range:ф35-ф110mm

Caps size range:ф35-ф95mm Machine weight:around 750kg